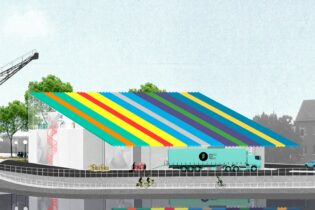

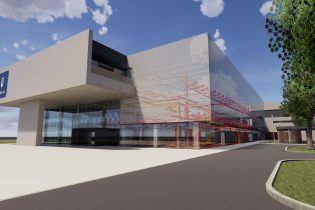

Sabert warehousing and employee facilities

Nijvel, Belgium, Europe

Total technical installations cost: € 1.218.803,72 VAT excluded

Total construction cost: € 3.200.000,00 VAT excluded

K Level: 20

Sabert, a manufacture of all types of plastic packaging for the food industry, was in urgent need to expand their warehousing capacity and their employee facilities to include washrooms, changing rooms and a cafeteria. For this reason a new building was designed whereby the warehouse would account for the main volume of the new building, with a smaller volume to accommodate the additional needs of the employees.

A gas condensing boiler was chosen to fill the demand for domestic hot water and space heating, and a ventilation system type D with heat recovery was chosen for the employee facility space. Gas-fired air heaters and an extraction ventilation system were installed in the warehouse.

Extra precautions were taken with-regards-to fire protection engineering, by installing smoke and heat extraction units that were integrated in the roof hatches, in combination with a sprinkler system covering the entire warehouse which also feeds the main water line to the fire reels. Due to the great height of the warehouse facility a specific fire aspiration detection system was installed.

Regarding the security system of the building, a comprehensive application of access control with badge readers as well as intrusion protection and facilities for camera surveillance was chosen.

Since electricity constitutes a major portion of the total energy consumption for the operation of the warehouse, LED lighting fixtures were selected and installed.

Finally, located on the roof of the warehouse is an extensive photovoltaic installation.

620 panels with a peak power of 280 Wp are provided with a total installed capacity of 174 kWp per panel.