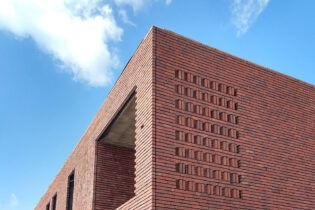

‘TER POTTERIE’ RESIDENTIAL CARE HOME

Bruges, Belgium, Europe

Total technical installations cost: 5.952.467,65 € vat excl

Total construction cost: 21.744.924,39 € vat excl

Surface: 10.738 m² (121 units)

K-level: 29

This residential care home consists of 121 rooms, accompanying nursing stations, living room/lounge areas, bathrooms and central storage. A relatively high ambient temperature and consumption of domestic hot water make this home a very energy demanding building. Due to the 24/7 constant occupation rates regardless time of day, this facility was an excellent candidate to introduce the use of geothermal energy.

On the grounds of the nursing home a BTES (borehole thermal energy storage) field is installed in order to equip the whole building with concrete core activation. 4 heat pumps (2 in basement and 2 in the attics condensing boilers) provide the circuits that operate at a low heating mode and cooling circuits, that operate at a high cooling mode. The boilers provide hot water production and during the peak demand times during the heating periods. The boilers can also be activated as emergency power supply for the concrete core activation. All areas are supplemented with radiators as quick adjusting temperature elements if necessary. The installed concrete core activation is utilized for both the heating and cooling of the building. There are no active cooling elements placed, cooling occurs passively.

Through the use of vertical boreholes (75st – 90m), the building provides its own energy for heat generation, thus reducing the need for fossil fuels. Fossil fuels are only utilized for the production of high temperature hot water. The vertical holes ensure the soil acts as an energy storage medium. During the extraction of heat, which occurs during the winter months, the soil is brought to a lower temperature. This free energy is obtained from the cooled soil and in turn is used to chill water used to cool the building in the summer months. Due to this interaction, there is continuous regeneration of the soil during a full year term. This guarantees the power supply required for both cooling and heating of the building. Electrical auxiliary energy is only utilized to operate the heat pump.

An intensive building management system of power, that accurately monitors and adjusts if necessary each parameter of the installation.

Concrete core activation is fitted in the floor slabs of the building, with the exception of the ground floor. Here, the concrete core activation was replaced with floor heating which also operates in a low heating and a high cooling mode.

A new HV cabin was installed to serve multiple buildings on the site. In the basement of the nursing home is an emergency standby generator with the capacity to take on the full operational needs of the home in the case of a power failure.

In order to maintain consistent quality patient care, the facility must scale communication, workflow and asset management. This translates into ensuring that each patient receives a timely and appropriate response to their calls. An advanced nursing call system was chosen, that may be accessed via multiple access points using mobile devices, with a robust reporting capability, and are adaptable to multiple users and needs (such as access control).

LED lights were utilized to reduce energy consumption. In the corridors a regulation is applied to control the use of artificial lighting reducing the number of burning hours.

Built on the slope of the roof are PV panels which ensuring the compensation of a portion of the electrical power consumption (cost price not included in the tender price)